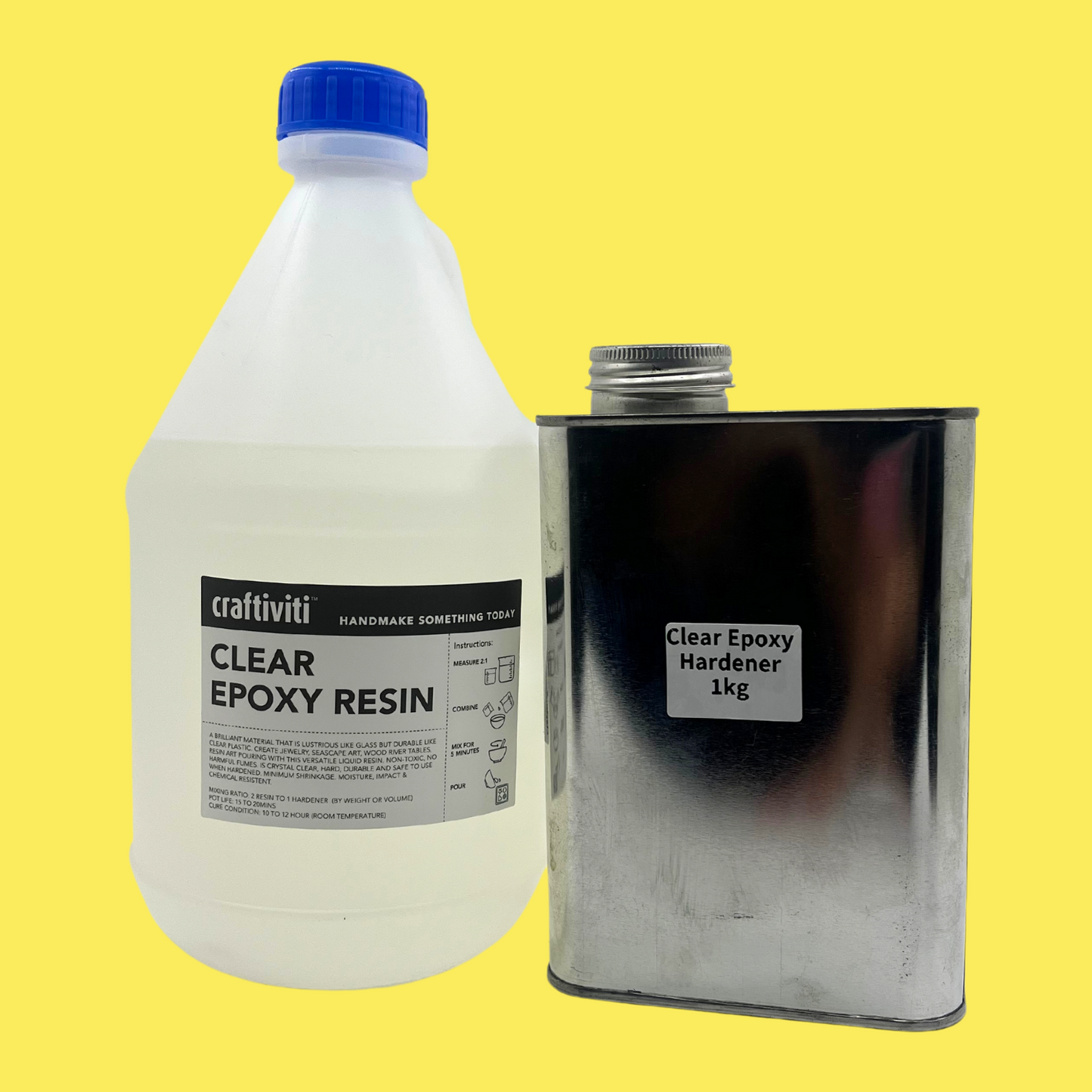

Craftiviti

Clear Epoxy Resin & Hardener

Clear Epoxy Resin & Hardener

Couldn't load pickup availability

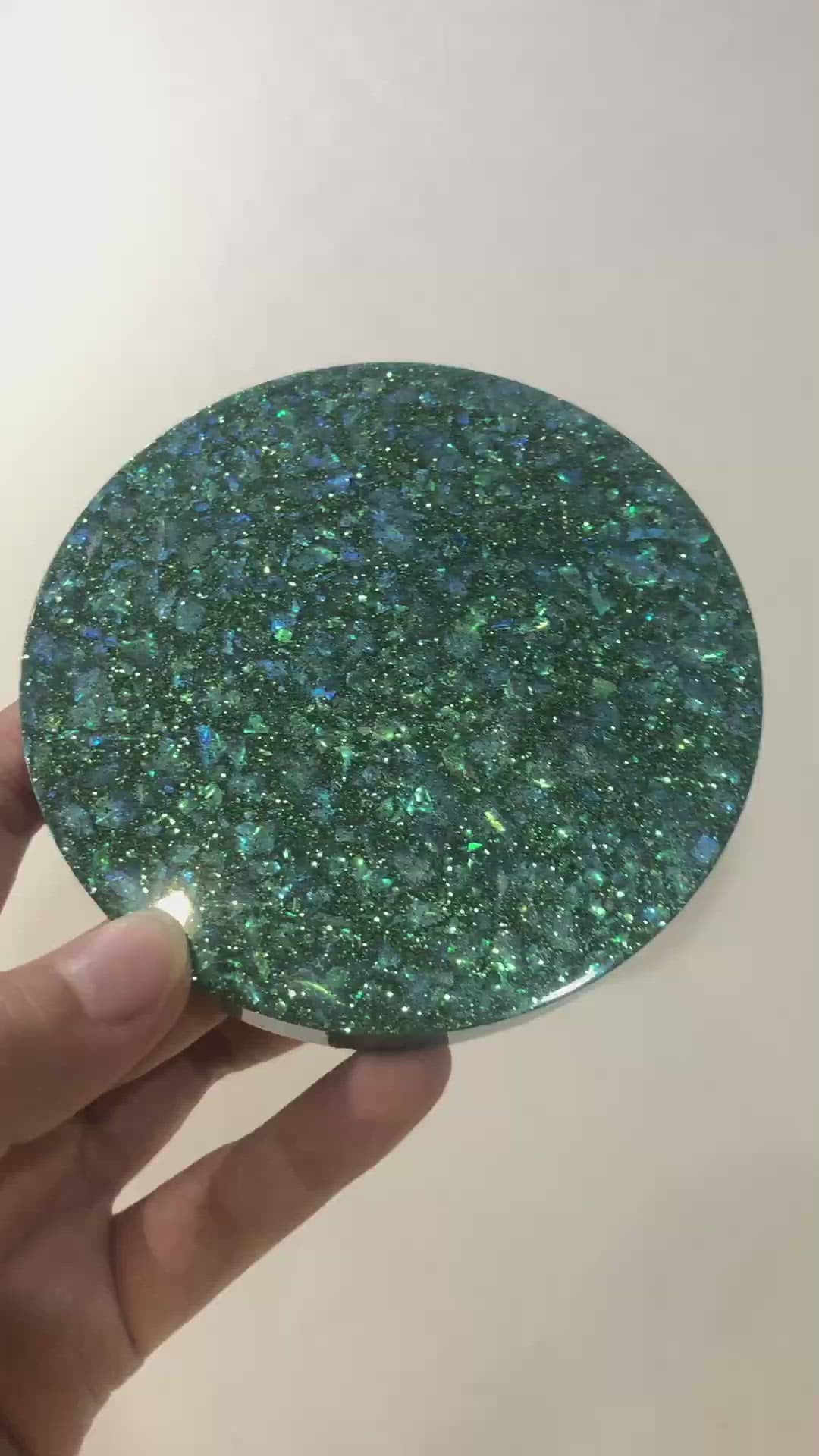

Epoxy resin or AB resin is a brilliant medium that's lustrous like glass but with a composition like plastic. It pairs form with functionality, resulting in endless artistic possibilities like fairy pendants, seascape art, pseudo-marble vanities, wood river tables, fishbowls and more.

Unlike polyester resin or Polyurethane resin, epoxy resin is non-toxic, odourless and does not give off poisonous fumes. The hardened epoxy resin is very clear, hard, durable and safe to use.

Shelf life: 2 years (unopened), 3 months (opened)

_______________________________________________________________________________________

SDS-Clear Epoxy Resin and Hardener

Shelf life: 2 years (unopened), 3 months (opened)

Mixing ratio for Craftiviti Clear Epoxy Resin is 2 parts Epoxy Resin : 1 part Hardener

Advantages:

- Minimal shrinkage during curing

- Excellent moisture and chemical resistance

- Good electrical properties

- Increased mechanical and fatigue strength

- Impact resistant

- No volatile organic compounds (VOCs)

- Long shelf life

- This is an AB resin / AB Epoxy Resin

- Contains 2-part resin and 1-part hardener

Specifications

- Appearance : Clear Liquid

- Viscosity (CPS) : 3,000 3,500 (Epoxy Resin) / cps 100 150 cps (Hardener)

- Mixing Ratio (by weight) : 2-part resin by 1-part hardener

- Pot Life (50gm) : 15 minutes - 20 minutes

- Shelf Life : 3 months (opened)

- Cure Condition : 10 hours - 12 hours (Room Temperature)

- Compression Strength : 728 kg/cm2

- Flexural Strength : 297 kg/cm2

- Tensile Strength : 136 kg/cm2

- Flash Point : > 300°C (Epoxy Resin) / > 150°C (Hardener)

- Cures to a Shore D70 hardness - this is subject to mixture precision and other variables

Instructions:

- Protect work area with a freezer paper, newspaper, wax paper, plastic sheets or silicone mats

- Before measuring, make sure the resin in the can is well stirred

- Mixing ratio for Craftiviti Clear Epoxy Resin is 2:1

- Measuring can be done using measuring cups or electronic scale for better precision

- Measure both parts carefully and in separate mixing containers

- Mix both components into a third container and give a good stir approximately 1- 2 minutes

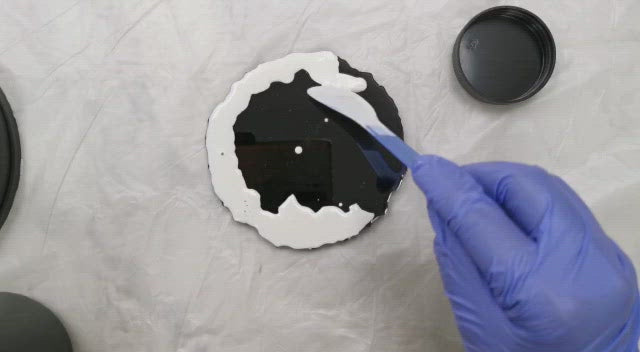

- Resin color pigment in liquid or powder form can be added into mixture (optional)

- You can also add in thermochromic pigment or glow in the dark powder for special effects. Thermochromic pigment changes color with heat.

- Apply release agent on mold surface before pouring the resin mixture

- Slowly pour the resin mixture into silicone or plastic base molds to prevent bubbles

- Bubbles can be dissolved by applying heat with a heat gun and dispersing the bubbles with a toothpick. The bubbles can also be dissolved with the use of a vacuum chamber.

- Curing time will be 24 - 48 hours depending on the size of the mold

It is always advisable to experiment before proceeding with the real project.

Please take note that resin will turn yellow as time passes as with most resins. To avoid yellowing, tint epoxy with colours/pigments or use it against a colored background.

Share