Emulsification: The Science of Creams and Lotions

Unlocking the secrets behind silky creams, stable lotions, and why some emulsions fail.

What Is Emulsification?

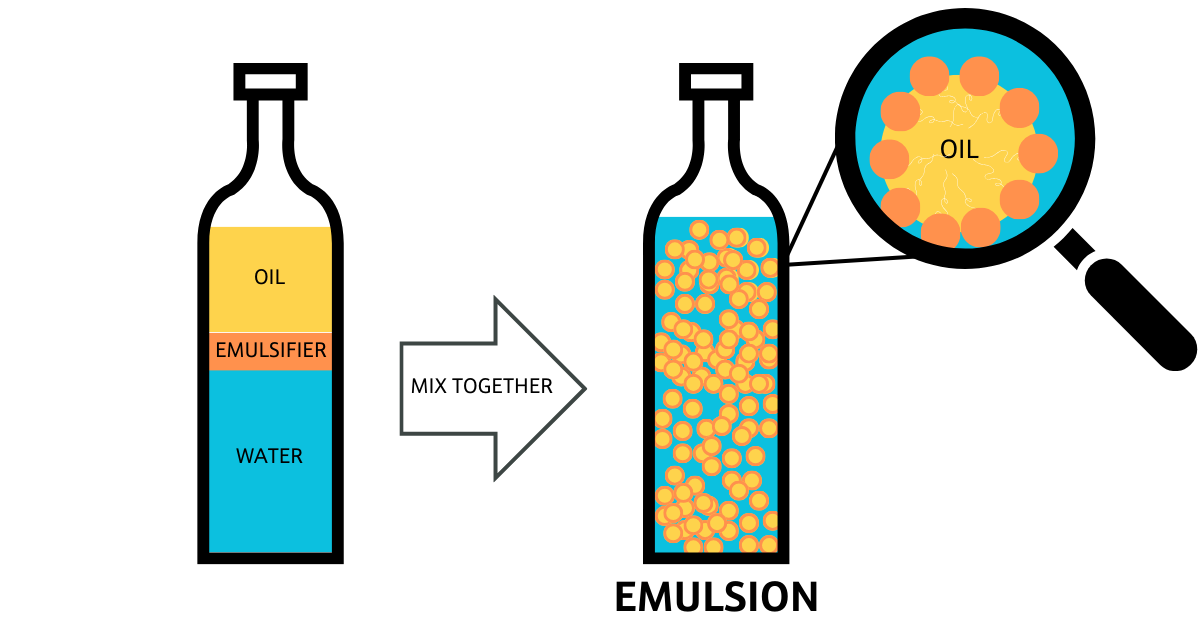

An emulsion is a mixture of two immiscible liquids — typically oil and water — where one is dispersed in the other in the form of droplets. Creams and lotions are usually oil‑in‑water (O/W) emulsions, meaning oil droplets dispersed in a continuous water phase. To make them stable and feel good on skin, you need emulsifiers, stabilizers, and the right formulation technique.

Emulsification science involves:

- Hydrophilic‑Lipophilic Balance (HLB) – matching emulsifiers to oil phases.

- Surfactant / Emulsifier effectiveness – how well the emulsifier reduces interfacial tension.

- Processing – temperature, mixing speed, order of addition.

Polysorbate‑20 vs Polysorbate‑80 — Basic Properties

Craftiviti provides great explanations of Polysorbate‑20 and Polysorbate‑80: how they differ, how to use them, and when. Craftiviti

| Feature | Polysorbate‑20 (Tween‑20) | Polysorbate‑80 (Tween‑80) |

|---|---|---|

| Primary fatty acid | Lauric acid (shorter chain) | Oleic acid (longer chain, unsaturated) |

| Solubility | Very soluble in water and glycerin; partial solubility in oils and butters | Soluble in water and in oils & butters; less so in glycerin |

| Best use case | Formulations with lower oil content (< ~5%) — e.g. mists, sprays, hydrosols with essential oils | Formulations with more oil — e.g. richer creams, cleansing oils, serums, oils + water blends |

| Color / Smell | Pale yellow, nearly scentless | Yellow, also scentless |

| Ratio use (oil : emulsifier) | Usually 1:1 with the oil or fragrance/essential oil when making simple mixtures like sprays | Similarly, match oil content; emulsifier amount ≈ oil amount when using Polysorbate‑80 for larger oil content |

Olive in Lotion Formulations (“Olive m / Olive m‑style”)

By “Olive m” I assume you refer to formulations featuring olive oil or olive derivatives (Olive m could be shorthand or brand/style). Olive oil (or olive fruit/leaf extracts, olive squalane, etc.) is a common and highly valued lipid phase in creams and lotions because of its skin‑friendly fatty acid profile, antioxidant content, and moisturizing & barrier‑supporting qualities.

When using olive oil in a lotion:

- Choose the right ratio of oil phase (olive oil + other oils/butters) vs water phase.

- Use an emulsifier system (Polysorbate‑20 or 80, or combined with others, or CP lotion makers/emulsifying wax) to ensure the oil disperses evenly.

- Ensure compatibility: some emulsifiers may not work well with heavy oils or butters without co‑emulsifiers or waxes.

Craftiviti’s workshop descriptions include using Craftiviti Refined Coconut Oil etc., but the same logic applies for olive oil or olive derivatives when you want a richer cream or lotion (e.g. CP lotion).

Craftiviti CP Lotion

Craftiviti CP Lotion

- The CP Lotion Maker can be used with distilled water (water phase), oils (coconut oil or other carrier oils), fragrance/essential oils, preservative and more.

- In such formulations, you can use Polysorbate‑20 or 80, depending on how much oil you include, to help the oil/fragrance disperse or emulsify properly if you’re not using a heavy emulsifying wax.

How to Choose Between Polysorbate‑20 & 80 in Your Creams & Lotions

To pick the right one:

1. Oil content / type

- Light oils, fragrance oils, essential oils + low water ratio → Polysorbate‑20 may suffice.

- Richer oils, heavier oil proportions, butters → Polysorbate‑80 or emulsifier blends.

2. Desired texture and stability

- If you need a thin spray or mist: low viscosity, less oil → Polysorbate‑20.

- For lotion/cream (thicker feel), long‑lasting emulsion → Polysorbate‑80, possibly in combination with waxes or thickeners.

3. Solubility & compatibility

- Polysorbate‑20 is more hydrophilic; might struggle with large oil phases.

- Polysorbate‑80 handles oil phases better.

4. Ratio rules (from Craftiviti & general practice)

- For simple oil + fragrance/emollient + water: match the grams of Polysorbate with grams of oil/fragrance/essential oil. E.g. 5g oil → 5g Polysorbate‑20 if using light oil.

- For stronger emulsions or lotions: often emulsifier + emulsifying wax + co‑emulsifier + thickeners.

Practical Steps: Making Stable Lotion Emulsions

Here is a step‑by‑step guide to create a stable cream/lotion using Polysorbate solid/emulsifiers; using Olivem in the oil phase; optionally using CP Lotion Maker etc.

Ingredients Example

* Distilled water (water phase)

* Olive Oil (or olive fruit oil, or olive + lighter oil mix) (oil phase)

* Polysorbate‑80 (or Polysorbate‑20 if oil content low)

* Emulsifying wax or CP Lotion Maker (if available)

* Preservative (e.g. those general‑use safe for creams)

* Additional actives: vitamin E, glycerin, humectants etc.

Procedure

1. Measure phases properly: Decide percentage of water vs oil. E.g. 70% water / 25% oil / 5% emulsifier.

2. Heat both phases (if using wax/emulsifier needing melt): Bring oil + wax + emulsifier to around 70‑75°C; water phase also to similar temp.

3. Mix oil + emulsifier first: Especially for Polysorbate systems, pre‑mix oil + Polysorbate (or Polysorbate + wax). This helps ensure emulsifier is well associated with oil.

4. Add water phase slowly to oil phase (or vice versa depending on emulsifier instructions) while mixing with shear (stir, mixer, homogenizer).

5. Cool with stirring: As the mixture cools, continue gentle stirring to avoid phase separation.

6. Add heat‑sensitive ingredients later: Fragrance, essential oils, preservative only when temp drops below ~40°C.

7. Test stability: Check for separation, creaming, or graininess over time & under different temperatures.

Common Problems & Troubleshooting

| Issue | Possible Cause | Solution |

|---|---|---|

| Lotion separates (oil rises or watery layer below) | Insufficient emulsifier; ratio of oil too high for emulsifier; poor mixing or temperature mismatch. | Increase emulsifier (or use Polysorbate‑80 instead of 20), ensure proper mixing, maintain temperature. |

| Lotion too runny / low viscosity | No thickener or wax; emulsifier but no stabilizer; oil too light. | Add emulsifying wax or thickness agents; adjust oil types. |

| Lotion feels greasy or heavy | Oil phase too large; using heavy oils with inadequate emulsifier/waxes. | Reduce oil, choose lighter oils, increase water phase, or use blends. |

| Lotion grainy or white specks | Oil crystallization, wax not fully melted, or cooling too fast. | Ensure full melting of wax, slow cooling, perhaps add co‑emulsifiers. |

| Fragrance / essential oil not dispersing | Using wrong Polysorbate (e.g. 20 when you need 80), order of mixing wrong. | Pre‑mix fragrance with appropriate Polysorbate, then add to water phase. |

Emulsification is both science and art. Polysorbate‑20 and Polysorbate‑80 are powerful tools in your formulation toolbox, knowing their differences, strengths, and limitations lets you design lotions and creams with desired texture, stability, and skin feel.

If you’re working with Olivem or CP Lotion approaches, mix well for stable cream and lotion.

Check out our website at Your Personal Care Materials & Therapeutic Crafts @ Malaysia or visit our retail store at Craftiviti, Level 2, Centrepoint Bandar Utama.